Connoisseur Standard 20 ton BR Brakevan

| Failed to open database: gaugegu1_gog2 | ret is false |

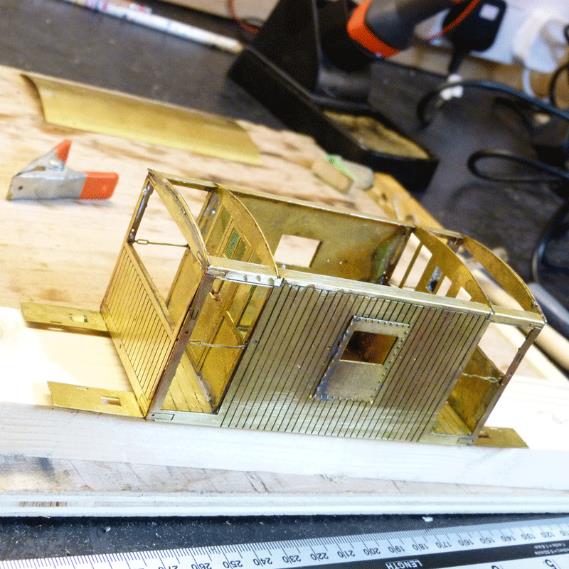

I thought I better post this up to give an idea of my early days soldering skills …….. or lack of. it is one of my first attempts as such and will be full of cabbage patch soldering and school boy errors but without it, there is nothing to gauge my progress against so here is where I am at the moment.

I have started on the sole bars and find the detailed smaller parts an even bigger challenge requiring more cleaning

up effort than soldering effort.

There really is not as much solder as the image might suggest. I still have bit of cleaning to go though. Anyway ……… much more to go. I'll post up a bit more as I go.

cheers …. and go easy on me.

Buckley10339 - Dec 30, 2017 at 9:19 PM

Bending bars are vital when folding sole bars and the other little thing that improves the fold is to go down the fold line twice with a scalpel or the tip of a very fine file to deepen the fold - not too much just enough to get the part to fold up crisply. Normal folds in the etches mostly do not need that only if its a fold close to another or an edge. The two metalsmith ones i have are about 6ins and 12 ins basically the large and the small ones.

Pat.

A bottle of solder paint [or paste] is handy for soldering small details on the outside, if you don't already have one. Less cleaning up to do.

David

Toto - Dec 30, 2017 at 10:13 PM

Thanks for your comments. they are all greatly appreciated. the guards handrails leave a lot to be desired. they have taken a battering and I was in two minds whether to take them back off and possibly make up others from scrap etch. I soldered them on pretty near the start of the build as per the instructions but in hindsight should have left them until later for two reasons. One they would be less open to being knocked as early and secondly i may have mastered the use of the iron a bit more carefully by the time I got to putting them in nearer the end of the build as the solder is a bit clumsy and would easily be seen at closer inspection. I may still change them yet.

I am assuming the solder paste is much the same application as flux. just dab it were its required between the parts and apply the iron ? I may have solder paste in my lotions and potions store :D I'll double check …….. I have just about everything else.

I have two sets of bending bars. one 11“ and one 7” set. I did use them but there is not enough room to get a second bend formed 100% due to the closeness of the two bends.

Again thanks for your kind comments and I shall post up my progress as it happens …… hopefully tomorrow.

cheers

toto

Davenport20954 - Dec 30, 2017 at 11:23 PM

A Hold N Fold tool is a help with such projects; but all looks well so far. A small suggestion is to add a piece of brass sheet over the veranda. Keep the wagon square when soldering. This will stiffen the whole body and strengthen the thin curved sections. The roof can then be glued to these. A nominal interior is also an option.

David

Toto - Dec 30, 2017 at 11:31 PM

Hi David,

Thanks for that. I have some brass etch that will fit the bill nicely for the verandah roof. i think it will go a long way to providing the extra strength. I'll have a go at cutting that to size tomorrow. Like wise the interior. It looks reasonably easy to cut and add in. Nice touch.

many thanks

toto

Toto - Dec 31, 2017 at 1:19 AM

Hi David,

One other thing, at what point did you install the floor and interior at ?

Toto

Jinty 47479 - Dec 31, 2017 at 7:36 AM

M&M Models do an item called a Sol-Y-Bar which allows you to make the second fold on the solebar. I've found it quite valuable for etched solebars.

http://www.modelrailwaywagons.co.uk/Mustard%20Page.htm

I take it that the van is the Jim McGowan kit?

I built this kit a short while ago and it goes together very well indeed, as do most of Jim's kits from what I understand.

If this is you learning to solder, you're doing an excellent job with it. Jim's kits are great for the beginner as they are both thought out well and are etched well too. If I was to say one thing though, maybe run a sharp blade down the inside of the folds to assist with the folding process and give a clean corner. Not to cut through, just a score along the etched fold line.

Keep up the great work

David

Buckley10339 - Dec 31, 2017 at 8:34 AM Jims kits are wonderfull, i have done 14 locos with my second B12 waiting and it must be allmost 40 wagons and an odd coach.In all the time i have been doing them i have never had any sort of problem with any of the kits they have all gone together perfectly.They are the best range of kits to learn on and Jim is allways there to give a helping hand.I cannt stress how good they are and i am going to carry on in 2018 with more Of them ! There i have got that off my chest ! Pat.

Turnbull21603 - Dec 31, 2017 at 9:54 AM

Toto,

if you can get hold of a copy of Jim McGeown’s “O Gauge Etched Kit Building” booklet you will find it invaluable.

The booklet has lots of very useful tips about every aspect of model making in brass as well tips on basic tools, electrics and so on.

I began in O Gauge after downloading this booklet from Jim’s website and managed my first locomotive by reading and referring to it through the build.

Regarding bending bars I initially had made a 12” set from 1” x 1/4” steel as shown in this book. These and a second similar shorter set, are all I use as they do allow a sole bar to be bent into the correct channel shape. I would suggest that you talk to Jim and see if the booklet is still available.

Keep up with your modelling, you appear to have made a good start, and remember “practice makes perfect”.

Les

PS. I have just looked at the Connoisseur Models website and the little book is still available.

Open the link to PDF down loads and you will find the booklet and other useful hints and tips.

Davenport20954 - Dec 31, 2017 at 10:44 AM

Toto.

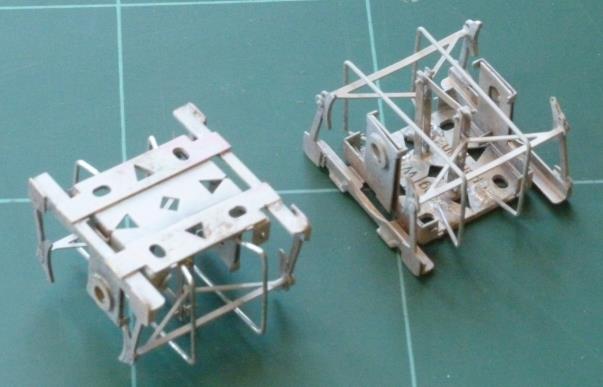

The interior was all done via the roof opening hence the heavy soldering etc. However, it is not going to be subject to close inspection! There are those that will think it a waste of time; you could just fit foggy glazing. However, engineering challenges, like hinging the doors, is all part of the enjoyment of making something. I also used Jim's compensation units fitted with bolts and captive nuts, and with added extra brake detail.

For small items like lamp brackets I tend to drill and fit them with scale rivets. Soldered from the back they provide a cleaner external join and are less likely to come adrift.

If you are new to the hobby then consider using Canopy Glue to fit glazing. It dries clear and is designed for Perspex. (it is a bit of a fiddle but do glaze the duckets; it looks so much better).

Keep up the good work.

David

Toto - Dec 31, 2017 at 10:58 AM

Thanks chaps,

I'll get a copy of Jims booklet. Sounds like a good place to start. The internals is just really to add a little something of my own and the extra weight won't do any harm. The drilling and riveting maybe a step too far for me at the moment as I am still trying to get used to working with such small parts. It's this that I struggle with most so that's maybe further down the line but I admire the determination.

I'll look into the sole bending bars as they will give a better finish. You could bend car parts with mine. :). One thing I find as well is trying to keep the etches clean. What are you guys using. Is there a good degreaser that might help take off some of the surplus flux etc?

Many thanks for all your inputs as it all very helpful.

Cheers for now.

Toto

Toto - Dec 31, 2017 at 11:08 AM

Large and small Sol- Y - Bar on there way. Somebody has kept that site a secret. Thanks for the link.

Toto

Davenport20954 - Dec 31, 2017 at 11:23 AM

Re cleaning of work, there are a few options and each has their own favourite. I use Bar Keepers Friend (Tescos) which is a cleaning powder. Used with a stiff 1“ paint brush and warm water it cleans things well. Dry with a hairdryer and undercoat while still warm; a can of etching primer being my tool of choice.

The fibre glass pen is another good tool but use with caution, maybe under a warm tap, to keep from breathing the fibres.

Be firm with the cleaning as it is better to have things fall off at this stage than when it is painted!

You can see the sole bar on my wagon is a bit rough but that is how that get after years on the rails. If you go on to weather the van then crisp, out of the workshop detail, is not a concern.

David

Davenport20954 - Dec 31, 2017 at 11:30 AM

I would add that the doors on the 20T van were a separate etch as opposed to the ones on your van which seem to be part of the etched sheet. I also used a thicker bar section for the footboard hangers to make them less liable to bending when handling the van; though I am sure that may just be me over engineering again.

David

Toto - Dec 31, 2017 at 11:41 AM

Jim recommends soldering some stiff wire to the rear of the footplate hangers to help strengthen it so I don't think you are over engineering. It's probably required.

Toto

Paul Bartlett - Dec 31, 2017 at 12:28 PM

How do you get the wheels in?

Paul

PS there is no ceiling to the verandah of BR brake vans, and the corner posts are solid.

Turnbull21603 - Dec 31, 2017 at 12:46 PM

Paul,

You remove one wheel from the axle, quite easy as they are a push fit, thread the axle through the bearing and refit the removed wheel.

I have used these for over a dozen scratch built four and six wheel coaches ever since Jim introduced them some years back.

Les

Toto - Dec 31, 2017 at 1:04 PM

Hi Les,

They look like a very nice piece of work. Intricate, well for me anyway put must be a pleasure to let folks see these. Just taking the kit that bit further. First class.

Cheers

Toto

Toto - Dec 31, 2017 at 4:40 PM

Here is a little update on where I am with the solebar build.

a little bit of a scrape and a clean still required but its getting there slowly….

one more

on to angle brackets now.

cheers

toto

Davenport20954 - Dec 31, 2017 at 6:08 PM

Paul, the veranda 'ceiling' helps strengthen the body and just represents the underside of the roof structure; and so is not really a ceiling as such. You could scribe it with the roof planking if you wanted to. Adding a box section to the corners would be a good move. I did this on a G1 brake van and should have done it in the one above. I used wire prongs on the roof to friction grip inside the box section and keep the roof on. The version I made had the ballast boxes underneath and I used these to house batteries for all the lighting extras.

Being able to get close up pictures of the real van is such a help and these can be got by a day out to a museum or from an excellent reference web site like your own.

Good kits are a great way to construct a model but adding some extra prototypical detail, like box sections to frames, can raise the bar.

David

Toto - Dec 31, 2017 at 6:58 PM

A little further as sole bar one nears completion. Still a bit cleaning up and a bit straightening of the main frame but that will be done once I have the second side done.

a couple of pictures ……

another ……

as you can see still a bit of excess solder and gunk needs to be taken away …… last one for now…..

Not the clearest of images and things are maybe not quite as bad as they look . As I said ….. a bit more cleaning and tidying up and they should look a bit better.

many thanks

toto

Jim Snowdon - Dec 31, 2017 at 7:06 PM

[Referring to previous post] But you do have to remember that they are designed for 3' 7” carriage wheels, so that if used with 3' 1“ wagon wheels as here, they need to have the scale equivalent of 3” packing inserted between them and the underside of the wagon floor.

Jim

Buckley10339 - Dec 31, 2017 at 10:01 PM

Toto,little tip put the dodgy bended parts of the solebars to the floor of the van -try straightening first with big set of pliars if the dodgy bend is soldered to the floor its a lot less noticable and the nice straight bit can be seen clearly when looking at the van.

Pat.

Toto - Dec 31, 2017 at 10:52 PM

Thanks for that Pat. I'll give it a bash or should I say try

Hulock13839 - Jan 1, 2018 at 12:33 AM

Are you sure about that Jim? The Connoisseur D1657 was an updated version of the D1659 of 1924 which was a M.R. design. I've recently completed one of these and used 3'1“ disc wheels and am sure I would have noticed using the wrong diameter. The earlier 10T vans (a la Slaters) certainly had 3'7” wheels (spoked) but I didn't think these did - I'll have to check my reference books when I get home.

Cheers,

Ray.

Jim Snowdon - Jan 1, 2018 at 1:04 AM I was referring to the suspension units, which are sold separately, not the kit itself. Jim

Davenport20954 - Jan 1, 2018 at 1:08 AM

Toto

With the triangular fillets in place the orientation of the sole bar is now fixed. So I think inverting is not now an option. Find a bit of steel that fits into the sole bar, stick it in a vice as an anvil, then use a small pin (or planishing) hammer to straighten things up. A few bends and wrinkles will just add character! When folding any section it is better to fold along the whole length at once with a metal bar or wooden block. Bending it a bit at a time will lead to problems.

Having the right tools is always a boon. I would love to have a rolling bar machine but have gotten by so far with a broom handle and a piece of carpet to roll a boiler. Necessity is the mother of invention.

David

Toto - Jan 1, 2018 at 12:52 PM

Thanks for that David,

I'll straighten out as best I can. As you say, a little bit of character. ( thanks for the get out ) :)

I'll be back in the shed later today so hopefully sole bar number two will be on its way. Whilst still rough, I do feel that I am getting the picture a bit more. The change in soldering iron and smaller tip has helped to get used to using less solder. That in itself is bringing around improvements. Hopefully as I make my way through some of my wagon builds others will be able to see my technique and therefore the finished items improving.

I starting to enjoy this.

Toto

Toto - Jan 1, 2018 at 1:41 PM

So much so that I'm thinking about going back and straightening some of the dodgy bits from earlier in the build. For instance the guard hand rails on the Varanasi openings. The soldering left a little to be desired. The rails are also a little battered and I have a couple of spares that came with the kit so I will address it.

It won't drastically improve what has gone to date but these soldered joints have been bugging me even though half of them are actually inside the van where they can't be seen. It acts as a little challenge to hone my skills in reaching some of the awkward far flung places with a soldering iron.

Thanks again.

Toto

Buckley10339 - Jan 1, 2018 at 4:33 PM

toto, what wattage iron are you using to solder the handrails to the body. you need a mimimum 40w iron or even a 50w as the amount of brass that your trying to solder to will suck the heat out of the iron. When all the brass bits are attatched its often very hard to solder things like that on using a bigger iron say a 50 w will often do the job much easier and keep the heat on till the solder goes liquid then remove iron sharpish, a liquid solderflux that penetrates the joint may help as well to get a neat and strong joint.

Pat.

Toto - Jan 1, 2018 at 5:53 PM

Hi Pat,

I'm using a 40 watt iron and its just a cheap Dura tool version. Temperature adjustable. I'll tell you, what a difference using this and a smaller tip. I have been using it again today and apart from benefiting from a trial run yesterday …… its helped my soldering no end. I have about half a dozen others buts this is the tool for me…… see for yourself …….

todays efforts ……….

as compared with yesterdays efforts…..

100% tidier. The only other difference is that I ran out of Brandy and I'm now drinking Whisky Mmmmmm. Nah …… its the iron and a little bit of experience.

delighted with todays results so far …… now on to the triangular supports and the two small square end plates.

cheers for now.

toto

Bob Alderman - Jan 1, 2018 at 8:10 PM

Toto

Nowt wrong with your efforts. You're getting along very well.

Happy New Year.

Bob

Toto - Jan 1, 2018 at 8:37 PM

Thanks Bob,

The second sole bar has worked out so much better. A vast improvement. Back off to the shed shortly to crack on.

Many thanks

Toto

Toto - Jan 1, 2018 at 11:39 PM

Finished it off tonight. I have a couple of hours tomorrow morning so a bit more time to progress a bit further. I'll post a few more photo's up tomorrow morning.

Cheers

Tot0

End of thread