Broad Gauge Society GWR Broad Gauge Standard Goods

Prepared by: Tommy Day

Originator: Les Turnbull

| Failed to open database: gaugegu1_gog2 | ret is false |

I am currently starting a new project, though this build is a first for me. I am also a member of the Broad Gauge Society and this build is S7, Broad Gauge. Ultimately I hope to produce a Daniel Gooch designed Standard Goods tender locomotive.

The locomotive is made up of two kits one being the tender the other the locomotive, which can also be built as a “Banking class” 0-6-0 ST.

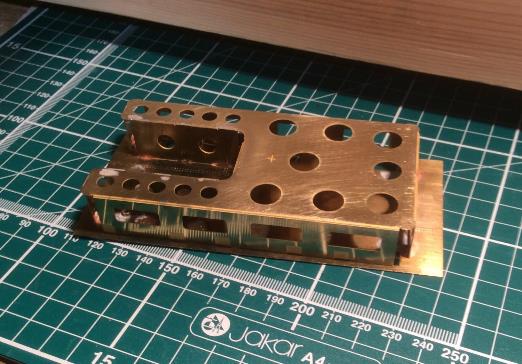

As is my usual practice I am beginning by building the tender, to get a feel for the kits. Firstly the tender kit is only etches and any castings need to be sourced separately. The other major point of interest is that there is no chassis, which becomes a scratch build job.

I drew up a chassis before starting, which I designed as an enlarged standard gauge chassis. That was a mistake as there is much more flexibility to overcome with 43mm between the frames rather than 25/26mm. Subsequently the centre was strengthen by triangulation.

The chassis is at a stage where it is ready for priming.

I am attaching photographs of progress to date.

Les

Grant18421 - Nov 8, 2017 at 2:16 PM

Is the tender kit the one from the BGS as I have one to built to go with my Scorpio Armstong goods in BG

Turnbull21603 - Nov 8, 2017 at 4:47 PM

Yes Peter it is a BGS kit. I will be replacing some of the etches with both white metal and lost wax castings.

I am building the tender to run with “Europa” which as this particular locomotive was the only one rebuilt, and the last survivor of the class has brakes to all tender wheels and sprung buffers.

It will be virtually identical to those paired with the convertible Armstrong designed Standard Goods so may be a help to you.

As I said in the initial posting you will need to scratch build a chassis.

Turnbull21603 - Nov 17, 2017 at 6:25 PM

Since my first posting I have painted the chassis and fitted the 14BA steel screws to locate the brake hangers.

Today I completed prefabrication the frames, which will be fitted at a later stage, by soldering on the axle boxes. I made these from brass strip as I felt the etched parts were too flimsy and were actually hollow. Having completed the work on the frames I began the substructure of the tank. This is folded from a single etch and located by slots and tags to the front and rear. The coal space is completed with the addition of two etches for the sides.

After soldering the tank to the floor it was necessary to file back flush, the front and rear tags to allow the chassis to fit.

Attached are progress photographs, which show what a wide tender Broad Gauge locomotives were attached to.

Les

Turnbull21603 - Dec 4, 2017 at 7:00 PM

The Standard Goods build has been laid aside for a while as I wanted to finally complete my pair of singles. I made a fresh start early last week and found progress hard to achieve.

From where the tender was left the next operation was to clad the substructure of the tank. This included the tank top, filler and side, rear and coal space plating. The instructions leave a lot to be desired consisting of a few sentences and hand drawn sketches, so a lot of thinking and head scratching is required. The tank top went in without any problems, however the filler required reworking due to my miss interpreting the sketch. Next job was to fit the overlays to sides &c, which are in eight sections each requiring trimming to length. To make fitting a little more tricky the top of the flared sides taper down from the rear to the front of the tender. The rear and sides would be much better to fit if they were a single etch, or even two halves. However I can only assume that the designer was possibly working from a very old drawing, if at all. (The protype for this tender was built c1848 for “Lord of the Isles”.) But I digress.

The sides and ends &c were finally soldered into place using the top of the flare for alignment and cutting the return plate at the front, which required some filling with solder and fine cellulose putty. Also the holes for the handrails required to be redrilled. The tank was then primed in order to see wher further filling or sanding need to be carried out.

Next the frames were put in place together with overlays, springs, axle boxes and lower tie bars. I opted to use castings instead of sweating a series of small etches to form the spring hangers. I had a set cast from some that I had in my spare castings box. These were actually intended for under hung axles springs, but were correct for this tender. To fit these it was necessary to cut out , locally, parts of the frames to accept the castings. Similarly it was necessary to fabricate the axle boxes from styrene strip solvent welded to obtain the correct depth. Assembly of the springs was completed using low melt solder and axle boxes set in place using superglue gel and liquid once settled into position. The tie bars were soldered in place again using low melt solder due to the proximity of the styrene axle boxes.

Turnbull21603 - Dec 20, 2017 at 10:55 AM

The photographs show the completed tender ready for completing the livery. Since the last posting the rear coal board has been fitted, having been scratch built to match the low profile of the sides and cast tool boxes, from Laurie Griffin have been added. For comparison with Standard Gauge a photograph showing the Gooch 1848 tender along side of an Armstrong c1870 tender. The standard gauge tender looks quite diminutive by comparison.

Les

Haines10259 - Dec 22, 2017 at 3:15 PM

Very interesting Les. That looks like an alarm gong low down on one side - presumably connected to the train via a cord and those long curved arm brackets that are visible in 19th C photos. It's quite an odd position for it to be in. I wonder if it could be heard from the cab easily?

Turnbull21603 - Dec 22, 2017 at 4:14 PM

I would think that the gong was audible David. They were in use for a number of years even on the narrow (Standard) Gauge. The brackets that you mention were part of the succeeding arrangement and not in use with the gong, according to the photograph that I am working from.

The final model will be of “Europa” which was the last, and only rebuilt, member of a class of over 100 Standard Goods designed by Daniel Gooch. “Europa” survived to the end of Broad Gauge in May 1892. The gong replaced the travelling porter, who sat in an iron coffin shaped seat on the rear end of the tender, his duty was to monitor the train and alert the driver if any problem occurred with the coaches. The gong was replaced by the link to the locomotive whistle, the cord being carried through eyelets on the curved brackets fitted to the tender. and eventually to the communication cord that applied the brakes.

Turnbull21603 - Jan 14, 2018 at 6:20 PM

Construction of the locomotive has now commenced after production of drawings in order to decide order of assembly and positioning of any fixings as there is no chassis and the model is built as the original design, the sandwich frames directly supporting the superstructure and running gear. Additionally there are no actual instructions, apart from a list of the etches. Like all Broad Gauge locomotives there is no footplate between the cab front and front buffer beam. ( This is not obvious from any photograph of a Broad Gauge locomotive that I have seen.)

Many of the etches are very small parts requiring to be laminated together to form a larger item. To replace these, as with the tender, castings have been sourced and procured to make the build less time consuming.

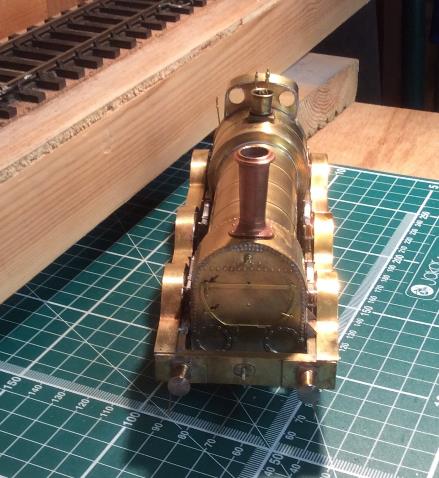

The mainframes have been completed so far.

Attached are photographs of the mainframes of the locomotive

The buffer and drag beams were prefabricated with all fittings attached. Inner and outer flitches were assembled and spaced with 3/16” brass flat bar to a position 28mm forward of the drag beam. This end section will carry the floor and cab together with arrangements for attaching the tender draw bar and fall plate.

Slaters hornguides have been fitted to the front and centre axles with fixed bearings for the rear driven axle.

Further progress will concentrate on building up the firebox, boiler and smoke box assemblies.

Les

Turnbull21603 - Jan 15, 2018 at 6:06 PM

The tender, shown in early postings was designed in 1847 the first example was paired with “Lord of the Isles” construction of this pattern of tender continued until about 1866. From 1866 new built tenders had the springs above the footplate.

The locomotive that I am currently building was a Daniel Gooch design, being a member of the “Caesar” class. These 0-6-0 tender locomotives were the largest Broad Gauge class consisting of 102 locomotives. The particular example that I am building was built in 1853 as part of the 5th Lot Goods

Les

Turnbull21603 - Jan 30, 2018 at 10:45 AM

The locomotive has now reached the stage where it is becoming to take shape and begining to look like a locomotive, however being a Broad Gauge machine designed by Daniel Gooch it seems very different. The original intention was to build a model of “Europa” which was the only member of the class to be reboilered and have a full cab. Having built up the firebox and soldered into place the cab floor I scratch built the cab, however I then came across a photograph showing the locomotive from an angle and realised that building of this particular locomotive was not possible. The photograph showed that the new boiler had a raised firebox similar to the Rover class and would require a special casting to produce the firebox front detail. It was back to the drawing board from this point.

The locomotive will be a copy of “Xerxes” which was in service until withdrawn at the end of 1882, this locomotive had a very short cab to protect the crew and a copy of this was built. The construction has reached the stage where the firebox,boiler and smokebox assembly has been substantially completed and ready for fitting to the main frames. The parts have been placed in their final positions, for the photographs, but not permanently fixed.

Turnbull21603 - Jan 31, 2018 at 7:45 AM

The only problem with the BGS locomotive kits seems to be a lack of instructions and whilst the etches are extremely good the small details are somewhat fussy and time consuming. Having said that the David Andrews kits have excellent instructions.

I have tended to source suitable castings where possible.

There are also other kits available from Scorpio, for convertibles, and Finney7 for the “Alma” class.

Les

Powell2517 - Jan 31, 2018 at 9:07 AM

Lovely to see some broad gauge models. Attached is photo of my Waverley class Lalla Rooke and Leo of the LEO class. These models run on 49mm gauge track and were scratchbuilt.

Rgds

Graham Powell

Turnbull21603 - Jan 31, 2018 at 11:34 AM

Lovely Models Graham. I find that naming locomotives, as in the case of GWR Broad Gauge, rather than numbering, gives them a personality.

Many of the old Broad Gauge locomotive names were perpetrated over the years, even a series of British Railways “Britannia” class carried former names used in the 1830’s and 1840’s.

Les

Grant18421 - Jan 31, 2018 at 1:18 PM

Having been a member of the BGS for a good many years I have felt that their 7mm gauge products to be of a decent quality, and maybe it's time for me to consider some of them. 7mm BG is so appealing I must admit.

Graham\

Hi Grahame

I have built a number of their 7mm kits and found them to be well thought out and a joy to build.

This months Broadsheet has some nice photos of locomotoves

Cheers Peter

Powell2517 - Jan 31, 2018 at 1:30 PM

Thank you Les. I ve made four altogether but I won't be making anymore. The names certainly can go back to the early days of the GWR. The plates were all made by Guilplates. All the best

Rgds

Graham Powell

Turnbull21603 - Feb 14, 2018 at 7:20 AM

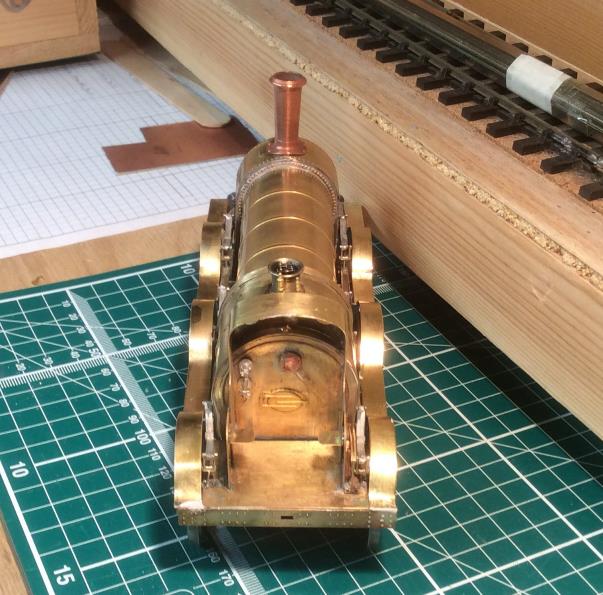

Since my last posting the locomotive has now reached the stage of final detailing.

The locomotive cab was again reworked to produce a reasonable facsimile of that shown for “Xerxes” photographed at Westbourne Park in the early 1880’s. The low side sheets have been preserved and a small cab roof and sides were added.

Similarly the locomotive is fitted with a Wolverhampton pattern chimney.

The firebox/boiler/smoke box assembly was fitted to the frames and held in place by brackets at the smokebox and firebox sides, four brackets in total. At this stage the crown of the firebox was lined with lead sheet (weight 57 grams) to balance the locomotive and add weight immediately above the driving axle. The ashpan was then attached, after cutting out part of the rear to allow fitting of a simple fold up gearbox and Mashima 1833 motor.

As previously mentioned this kit of etches comes without instructions and in the case of the set I had the nickel etches were not identified. After requesting assistance through the BGS yahoo group I was sent the missing sheet plus a drawing of Gooch’s valve gear. The inside motion was then put in place, although I used castings from my spares box for the big ends. It was also necessary to widen the slot in the motion plate to correctly align the valve rods, the motion plate etch was strengthened before removing material to give an opening of 8mm in width. The motion will be eventually spaced on the axle, using suitable brass tube allowing ease of axial rotation.

The splasher/valance assemblies were then assembled, this being considerably time consuming and required the single length splasher top to be annealed before forming to the profile of the valances. The springs were fitted to their hangers prior to soldering the splasher/valance assemblies in place. The inside of the splashers was deliberately omitted, as the clearance to the back of the wheels was extremely limited, to avoid potential shorting out.

The final fitting of handrails, boiler fittings, etc remain to be completed.

It is not intended to fit pick-ups to the locomotive as they cannot be hidden due the the open framing. Pick-ups will be fitted to the tender for power collection, the tender will be linked to the locomotive for electrical continuity.

Les

Powell2517 - Feb 14, 2018 at 8:22 AM

Nice work on the splashers Les. They are tricky. The ones on Lalla Rooke took several attempts and were done with some thin brass sheet ( more like shim) that I had been given.

The bogie tank I built has splashers on the bogie to make life more interesting!

I used Mashima motors in my locos though they all drive on to nylon gears.

Rgds

Graham

Powell2517 - Feb 14, 2018 at 11:00 AM

Hi Les

Attached is picture of underneath of Leo. You can see the split axles and the nylon drive also the boiler lagged with wood. It has always been a brilliant runner.

Rgds

Graham

Turnbull21603 - Feb 14, 2018 at 12:44 PM

The timber lagging look very good from the underside Graham. I would like to see a photograph showing the whole locomotive, which I assume has a haycock firebox.

The splasher etch is 28.5 thou and needed a lot of heat, in several short bursts with intermediate cooling, to allow the bending.

I worked from the centre with the splasher top vertical and supported with a piece of wood resting against a heavy steel block. Using a “lolly stick”, these have a nice rounded end, to push the valence into the splasher top then soldered into place. Each side took about two hours to fabricate to my satisfaction. Very time consuming but the end result was well worth the time taken.

Les

Powell2517 - Feb 14, 2018 at 2:01 PM

Picture of Leo . Boiler lagged with model aeroplane thin plywood. The planks are scribed on with biro. The firebox was made from four pieces of copper sheet soldered together. It's cut away for wooden lagging on the vertical sides.

28thou for splashers sounds very thick to me. I used five thou brass. I cut out the vertical face first and then soldered on the top. I had several goes as I had to make sure the splashers did not touch the live wheels! These early engines are certainly different to build from the more conventional models which I find easy to build.

All the best

Rgds

Graham Powelli

Turnbull21603 - Feb 14, 2018 at 2:25 PM

I agree with you there Graham. The lack of a chassis is a major difference which in itself presents problems that you do not encounter with conventional locomotives.

Forming the curves for the splasher tops was not a new excercise to me having built two Dukes and a pair of singles, the only difference is that three curves are formed rather than two or one. I like the aesthetics of a curved footplate, hence my love of Victorian period GWR Engines.

Les

Powell2517 - Feb 14, 2018 at 5:01 PM

On the Bogie class the frames only carried the driving wheels. The bogie was fixed to a large casting mounted under the smokebox. In the reverse direction, the load would have been taken by the boiler!. They did not last very long……..

The Victorian/Edwardian locos were certainly very elegant and I always get the impression that the companies were very proud of their locomotives. I always think the LBSC was the most elegant railway but there were others . Apart from the broad gauge ones I have built an Irish 2 2 2 welltank and an Armstrong 4-4-0 (perhaps the most elegant one of all). One i definitely want to build is a de Glehn compound. I know there is an excellent kit but I wont be buying it. So many interesting locos but so little time.

All the best

rgds

Graham

Turnbull21603 - Feb 14, 2018 at 5:56 PM

I am also debating what to build next in the way of a locomotive and cannot decide between Broad Gauge and Standard Gauge. I am tempted into another Dean Single, or possibly a convertible of some description.

The next item on my agenda is a diagram V6 Post Office van, an old IKB kit and possibly conversion of a diagram K3 Standard Gauge PVB to diagram 16 Broad Gauge PVB, which will be an interesting little project.

Les

Powell2517 - Feb 14, 2018 at 7:07 PM

It's not my intention Les to build any more BG Models but one of my friends tells me I should build a Pearson 4-2-4 tank ! I m doing a load of Southern engines at the moment. It really is a job to know if I need any more for myself.

Rgds

Graham Powell

Turnbull21603 - Feb 15, 2018 at 7:46 AM

A Pearson 9’0” 4-2-4 Single would be a very interesting build. You can get etches for building thedriving wheels from the BGS, as you probably know. As I see it you would need to drive from one of the bogies as the driving wheel was flangeless.

Les

Jim Snowdon - Feb 15, 2018 at 7:56 AM

Not having a flange on the driving wheels should not be an impediment - after all, the tractive effort is transmitted through the treads, not the flanges, and with the guidance provided by the bogies, the driving wheel treads are kept on the rail heads anyway.

Jim

Turnbull21603 - Feb 15, 2018 at 8:13 AM

I take your point Jim, however I have seen both the driving wheel and a rear bogie complete with small motor and final drive which is intended for driving the locomotive when completed. The actual model is being obviously scratch built by a BGS member and the parts described did appear at Bury St Edmunds last year.

Les

Powell2517 - Feb 15, 2018 at 8:55 AM

If I ever did build it, the drive would be the rear bogie. Lalla Rooke has one pair of flange less driving wheels and that works okay. I have a pair of cast iron driving wheels but that's as far as its got….

Rgds

Graham Powell

Turnbull21603 - Mar 4, 2018 at 2:12 PM

Completed and ready for a final clean up and prime coat. The locomotive is standing on a trial piece, of baulk road, mixed gauge bridge rail track which is a pattern for a proposed mixed gauge layout in the future.

Les

Turnbull21603 - Mar 5, 2018 at 10:32 AM

I copied the details for the final arrangement of the Baulk Road, from the diagrams in The Great Western Way, modified to add the third rail from photographs, making a full size (7mm=1’0”).

The lengths of track are 18” long laid on 8×2 mm lime wood strip with 4×2 mm transom, which I purchased from Cornwall Model Boats. To attach the bridge rail to the base I soldered small coupons oh single sided printed curcuit board to the rails at both ends and the centre, these were drilled and pinned to the base. The The curcuit boards, on the final arrangement will be electrical connect to power the track. The actual rails were spaced using the necessary gauge setting tools.

Les

Turnbull21603 - Mar 15, 2018 at 3:28 PM

Finally completed only the name plates require to be fitted, once to hand.

The locomotive is modelled in it’s last configuration, with a cab, of sorts. The model is based on a photograph of “Xerxes” taken in the yard at Westbourne Park c1880.

Les

Turnbull21603 - Mar 15, 2018 at 5:27 PM

The theme of standardisation runs through the whole 110 years existence of the Great Western Railway. Every locomotive superintendent, from Daniel Gooch to George Jackson Churchward, made efforts to standardise. Charles Collet continued or updated previous designs only Fredrick Hawkesworth produced new designs the 15xx pannier tanks and the “Counties” being the exceptions.

The Standard Goods was actually the largest Broad Gauge Class, over 100 examples being built at Swindon.

Les

End of relevant thread