© Raymond Walley – All rights reserved. Transferred to Wiki by Tommy day

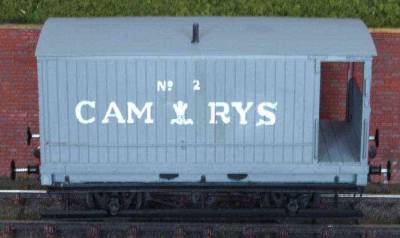

CAMBRIAN RAILWAY BRAKE VAN

This wagon was produced and reviewed by Raymond under the Dragon Models name. Dragon Models are now known as Taff Vale Models and are under new ownership

| Failed to open database: gaugegu1_gog2 | ret is false |

This is the next

vehicle in a train

of eight for a

client. It arrived

from the client in

a box partially

started but I

believe normally

comes as a flat

pack. The

instructions cover

six sides of A4

and include a

series of coloured

construction

pictures, some

prototype

information, a

dimensioned drawing and an additional couple of pages of prototype

information. Here are most of the parts laid out ready to start with the addition

of Slater's wheels and WEP compensation units.

The recommended start is to fit the sole bars and then the inner partition

however, looking ahead, I decided it would be easier to fit the ends and a side

first and then fit the partition. That way it can be correctly lined up with the end

of the cabin and avoid the natural tendency of fitting it in the etched line of a

floor plank. The ends needed the fold over that represent the buffer beam filing

down somewhat so that they are a snug fit against the sole bars. Once done, it is

a simple matter to solder them up square. Well, it should be but, as you can see

in the next picture, I did not quite make it and had to go back and straighten up

one corner.

The sides also

need some work

with a file to

open out the

notches at the

bottom corner so

that they are a

good fit around

the buffer beam.

Actually, a good

fit is not essential since they are covered by strapping plates later. I also left

fitting the long handrails until the body was assembled so that it would lie flat

on the bench when soldering. Normally I fit as much as possible in the flat but

this was one time that that was not appropriate. It is necessary to cut away a

small section of the upper fold over on the sides so that the partition will fit. I

also found that

this partition was

too tall and

needed filing

down a little to

get the roof to fit.

Here is the floor

before the ends

and sides were

fitted and you

can see that

several cut outs

were necessary

for the axle

guards and V

hangers to fit

perpendicular to it. The instructions do not mention this, but careful study of

the pictures reveals that something similar was done on the demonstration

model. It would have been much easier to have done this before soldering the

sole bars.

The cut-outs need to be about a millimetre deep. Ensure also that the ends of

the completed floor are filed off square, or the van ends will not sit properly,

which in turn will cause the sides to fall short of the ends. Dry runs are

recommended. Some of the parts are etched slightly over size, hence the need

to check and adjust, but better than being too small. The next job is to fit the

underframe detail. Checking the axle guards against the suspension units

indicated that they needed a 2mm thickness of packing to line up the holes with

the axles.

This small

problem was

overcome by

soldering some

short lengths of

rectangular brass

tube on the floor,

to which the

compensation

units were then

soldered. The

tube did not

require the vast

amounts of heat

that solid section

would have.

The underframe

detail is pretty

standard, now all

that is required

are the springs,

hangers and axle

boxes fitting.

The springs and

hangers come as

separate items

and clearly are

intended to be

fixed inside the

sole bars.

Unfortunately,

this is not

possible due to

the W irons being

in the way. I

used Loctite 408

to fix the springs

into the hangers and then cut away the remainder of the hanger portion so that

the combined spring and hangers could be fixed to the W irons with 408.

The axle boxes also need to have

their backs filed down flush to

be fixed to the W irons.

The axle boxes also need to have

their backs filed down flush to

be fixed to the W irons.

Here, the three parts have been fitted

to vehicle.

Completed and

awaiting a trip to

Dennis's paint

shop, after which

the glazing can

be fitted and the

roof firmly fixed.