Building the PH Designs KFA Container Wagon

Peter Warren - Gazette - August 2016 (Vol 19 No.12)

The Kit

I have often thought that these unglamorous wagons would make a good subject for a model - a mass of

structural framing with all the brake linkage and pipework on show - but LB&SCR models the opportunity has not

arisen to make something as up-to-date as this. I inspected a made-up example of

this kit at Telford and an order was placed – a real change from 9ft wheelbase wooden wagons.

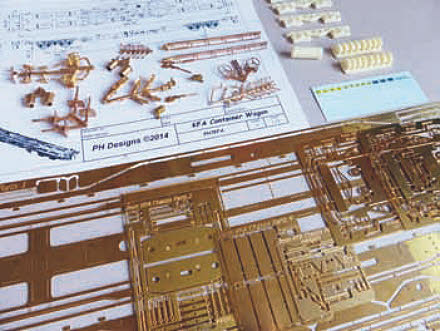

This is a highly detailed etched brass kit with a large quantity of lost-wax brass and resin castings.

It is not a rapid assembly production so look elsewhere if you want to build a long train of container flats over

the weekend. The quality of the design makes it possible to produce something of exhibition quality but it is

still robust enough to give good service on a finescale layout. So what do you get for your money?

The six etched sheets are of very high quality and very clean; some of the components like the little mesh grilles

are extraordinarily fine. The tiny etched tabs and slots generally proved to be an accurate aid to assembly.

The brass castings show a very high standard of pattern-making. The bogie side frames and brake blocks are highly

detailed resin castings with very little flash. Nine printed A4 sheets of instructions and a fine set of waterslide

transfers complete the package. To complete the model you need to add wheelsets (I used the recommended 2ft 10in

wheels from Peartree Engineering), brass rod and wire in various diameters for

the brake gear and pipework, and paint.

I mentioned the package; well do not expect a large box, the completed wagon is 488mm long. The kit arrived as a well wrapped brown paper parcel.

Disappointingly, the etched parts had been stuck to a piece of board with adhesive tape which is no doubt a cheap

and effective packaging technique, but care is needed not to damage the delicate components when removing the tape.

I used butanone as a solvent to clean it off.

The instructions are very professional looking drawings comprising plans, sections, exploded axonometric

projections and details of the model, suggesting a very thorough knowledge of the prototype and a well-engineered

approach to the design of the kit. The drawings show the suggested general sequence of assembly and written notes

are minimal. Surprisingly, no information is provided about the prototype and, having nothing relevant in my

pre-grouping library, I searched online to try to find out what I was about to build. A wealth of photographs

available, showing various types of KFA flat wagons and, noting that the supplied transfer sheet included

TIPHOOK RAIL insignia, I narrowed the search to a series of container

flats newly constructed for Tiphook by

Rautaruukki in Finland in 1988. So it’s not such a modern wagon after all. These colour photos included

good close-up detail shots which proved invaluable during construction.

The instructions are silent on recommending the best tools and techniques for assembly; soldering is the

obvious method and I used a resistance soldering unit and small amounts of Carrs solder cream for almost everything.

An 18W Antex iron fitted with a very fine bit was useful for getting into tight corners with small components.

Although I followed the assembly sequence indicated on the drawings, I was very disappointed there is no parts

list or any identification of the components on the various frets, so be prepared to spend some time finding

the right part and working out which way round it fits; many components are handed and very few have any spares.

Because the parts are not numbered you need to look at the drawings, which show the etched parts folded up,

and work out what they would look like before folding then try to find them on the etches.

Solving this 3D jigsaw puzzle added significantly to the build time.

Reducing the excellent drawings to A4 size has not done them justice either; it makes it harder to see the detail

of small folded parts and a larger scale print or a digital copy would have made this a better experience.

I discovered another problem with the exploded drawings is that whilst vertical lines have been added to help

show where parts go, they did not show the final locations very clearly. Much cross-referring was necessary to plans,

elevations and the afore-mentioned online photos.

Bogies

Assembling the Y25 bogies showed that the accuracy of fit of the various components was excellent, even where the components were made from different materials. The beautiful cast resin sides locate neatly on to an etched brass subframe; I used Araldite to bond these into place. Curiously the wheel bearings have to be bonded to the resin instead of being soldered to the brass subframe – beware of getting adhesive into the open ended Peartree bearings and locking the wheels up solid (don’t ask how I know this).

The resin brake blocks are highly detailed and you need to look closely to see that there are different types for

the inner and outer brakes on each bogie, and that they are handed. Removing 16 of them from the large sprues and

cleaning them up to suit the diameter of the wheels is tedious. After all that effort I decided it was worth

highlighting the gap between the two brake pads on each block with a little cut from a razor saw, and I also

pre-painted the pads the reddish colour I had seen in the online photos as it would be difficult to do this

after assembly.

Assembling the inner brake blocks on to their etched hangers was straightforward – I used Canopy Glue –

followed by bending the angle of the hanger to align with the wheel tread and soldering it to the adjacent

etched tab on the bogie frame. The outer brake hangers are more challenging. Each hanger has four tiny

etched parts and soldering these together is fiddly enough, perhaps it would have been better if they had been

supplied as brass castings. These then need to be fixed to the frame stretchers, three more etched

parts, and the brake blocks and yokes fitted. There are no spares for any of these small parts and I had to

allow extra time for searching for bits that dropped on to the floor. I fixed the hangers to the

stretchers, then glued the blocks in place, checking each block was the right way up and the handing was correct,

followed by the brake yokes, fixed into the holes in the blocks with araldite. All you have to do

then is solder the completed assembly to the bogie sub-frame, whilst checking that the brake blocks align with

the wheels. The finished result looks very good when compared with the online photos.

Having said that, the bogie design itself is fairly basic, without provision for springing or compensation,

although this is not really required for most finescale layouts. The instructions suggest the bogies are simply

bolted to the chassis with a compression spring to provide some allowance for rocking.

Mainframe

The lesson from the bogies was that all the components fitted perfectly but care was needed to find the right component and to make sure it was the right way round every time. The same applied to the main frames. The first thing to notice was the large number of little rectangles attached to the top edge of each girder; they are not shown on the drawings and after I had cut them off it occurred to me that they might have been intended as twist tags to hold the top deck in position on the tabs before soldering. I managed quite well without them. Secondly, the drawing on Sheet 3 implies that the bottom flange on each transverse girder is formed by a single wrap-around etch. This is not so, each is in three parts, leaving a gap to slot over the longitudinal girders.

Apart from that, assembly is straightforward – components tab and slot together well and are readily soldered

with tiny amounts of solder cream. It is important to keep everything square, straight and true. I used 0.5mm brass

wire to represent the weld lines over the bogies on the outer longitudinal girders, soldered into the half-etched

locations. The bottom flanges were soldered on to the inside face of the outer longitudinal girders, with the

notches facing in. I decided to put in all the various cross members on the main structure before adding the outer

longitudinal girders, followed by the diagonal bracing.

The pressed steel splashers over each wheel are represented by etches with fold down edges which may be to scale

but are so small that it is difficult to obtain a neat bend. These were rivet-punched and fitted

to their little support angles. Notice that these angles are handed before fixing them.

Buffer Beams

Work on the buffer beams began with cleaning up the excellent cast brass buffer housings. Do not drill out, the hole at the rear of the housing is hexagonal to prevent the buffer spindle from rotating – very neat. The little protrusion on the side of these spigots helps get the buffers level when soldering them to the buffer beam, but I still spent extra time getting them horizontal. More time was spent cleaning up the buffer shanks so they slid smoothly, and adding some springs from the stock box. To retain the buffers I used a 12BA screw inserted into a tapped hole in each buffer shank. I chemically blackened the buffer shanks but did not fit them until after painting. The buffer beams were completed by fitting the air brake hoses and grab rails. The grab rails below the buffers are not shown on the drawings but the fixing holes are etched. I checked the online photos again and added the grab rails using 0.6mm straight brass wire. I left the projecting lamp brackets off until all other assembly work was complete as I thought they would be vulnerable, but used some sturdy spare cast brass ones in place of the little etch supplied.

The coupling slot castings fit neatly on the rear plates to the buffer beams, although they cannot be seen on the

completed model. These rear plates need another of those very tiny folds before fitting the tabs to the slots in

the frames. The buffer beams were then tabbed and slotted into place, although this left a gap with the rear plate

which had to be filled with a length of 0.6mm brass wire soldered in and filed smooth. I also found that the tabs

on the end of the bogie mounting plates did not align with any slot in the buffer beams and needed to be filed off.

To provide weight little pieces of lead sheet were soldered in to the pockets shown on the drawing; I also added

some to the bogies as well. The bogie mounting bolts need soldering in place before fixing the top deck otherwise

a hole will be required in the deck, as I discovered.

Top deck

The top deck proved to be fractionally too long to snap over

the large number of tabs in the frames; instead of forcing it I cut it into two halves, the butt joints were

almost invisible after cleaning up. The RSU was used to solder each tab. At this point you discover how successful

you have been in keeping the whole chassis assembly square. I found small gaps under the buffer beam rear plates that

needed filling.

The coupling hook castings needed cleaning up, making sure they slotted into the rear spring castings. The screw

links were assembled on to the hooks with 0.9mm brass wire rod using oiled paper washers before fitting the hooks

through the buffer beam and soldering the rear spring in place. I decided that the whole coupling assembly should

be able to pivot left-to-right slightly against that radiused cast back plate fitted earlier. The etched

coupling protection box could then be added. It would have been easier if this had been etched in one piece.

Each of the 16 little twist-lock sockets is formed with a folded etched body which tabs into the frames, followed

by very neat etched tops which I found trickier to solder in squarely but they are one of the few components to be provided with

spares. The instructions note that two types of twist locks are provided, locked and unlocked, but these are difficult to

identify on the castings themselves. The locks project upwards from the sockets to engage the container or are recessed down

into the sockets when unlocked. I opted to show them all locked as I thought the tops of all the sockets would need to be drilled

out to represent the unlocked position. The operating handles for the locks are prominent in photos but not shown in the

kit. Although the castings have marks indicating where they could be drilled out, I was not able to achieve this and simply

soldered on lengths of 0.6mm brass rod after the locks had been soldered in to their sockets and trimmed to length.

Brake gear

With the main framework complete, fitting the brake gear could begin. Much study of the drawings and photos was required to be certain

how parts actually locate together and how they were supposed to look when complete. I started with the handbrake cross-shaft, using this

to locate the little bearing strips which in reality are bolted to the outside of the frames, followed by the neat cast hand

wheels. The larger plates which form bearings for the handbrake on/off indicators have half-etched areas implying

they are to be soldered on to the outside of the frames whereas photos show them flush with the frames. I bent the etched

areas back and soldered them to the underside of the framing to replicate this. I eventually worked out how the cast

handbrake screw thread and yoke slotted together with the etched angle supports although on the drawing the yoke is

shown with a projecting rod and clevis which was missing from my castings. I fabricated the missing rod from brass wire

and strip before fixing these components, but later found I had made it too short. The third cross-shaft is supported on neat

folded etched angle brackets. To assemble these, I drilled the small cast gearboxes for the cross-shaft before soldering them to

the brackets. With the cross shaft in place the brackets could be soldered to the chassis before adding the tiny operating

handles. The locations for the large KFA data panels were checked against the online photos.

Before fitting the main air reservoir, I drilled out one end and fitted a 0.6mm brass rod to represent the air pipe, bent to

disappear through a hole in the main frame, and added a little piece of 0.9mm rod to represent the drain valve at the

bottom of the tank. The air brake actuators and other castings fitted without difficulty, as did the large number of

sundry etched components.

The plan view shows how the various brake linkages go together. The lever arm etchings and other multi-layer components together with the

long cast brass brake rods were soldered up like loco valve gear, pivoted using various diameters of brass rod, before passing

them through the slots in the frames and fitting them as complete sub-assemblies to the air brake actuators. I added little supports over the

bogies for the outer ends of the cast brass brake rods from scrap brass, although it occurred to me that this may have been the purpose of

two unidentified etched forked components which were left over at the end. Could those large cast brass brake rods have been simplified to

a little casting which slipped over a length of brass rod?

Final details included the etched plates with mesh grilles, which I assumed may be modern versions of wagon label clips; these have etched

borders less than 1mm wide which will challenge any hold-and-fold, and required bashing on a flat metal surface to achieve a resemblance of a

flanged plate. The amazingly fine etched mesh was added (do not breathe on it or it will disappear forever), fixed with a tiny

blob of solder to represent the locking handle.

Builder’s plate

Painting and works plate

A surprising omission from the kit was the prominent Rautaruukki builders’ plates, clearly shown in the online photos.

I made my own by drawing them up on the computer and adding them into a corner of an etched sheet I was preparing for another project.

Having come this far and spent so much time studying the online photos I could not leave off some representation of the air

brake pipework. This was added in 0.6mm and 0.9mm brass rod, the kit has most of the required holes already included in the

etch. I also noticed a little release cord (marked ICD on the solebar), and what looks like an earthing connection from the

RH end of each solebar to the bogie, all of which I added from strands of fine copper wire.

In the paint shop I sprayed the framing with a mist of U-POL Acid 8 etch primer from an aerosol can before airbrushing

two thin coats of the prescribed Lufthansa Blue paint. I followed the online photos to pick out all the details in yellow, white

and red to produce an ex-works finish. The waterslide transfers supplied are by Railtec and are very

clear and add real quality to the model – trim close to the lettering before applying them. My attempt at sealing them with a little

varnish nearly ended in disaster when I discovered that the transfers were dissolving; Testors Dullcote was the only

one which didn’t have this effect. A little light weathering will follow later. Online photos show a range of possibilities for

heavy weathering addicts.

I thoroughly enjoyed building this wagon and I have tried to be constructive in my comments when difficulties were encountered.

I had never tackled anything quite like it before and it pushed me out of my comfort zone, as a good modelling

project should. It was a major project which required hours of thinking and studying of photos as well as testing my

construction skills. As such I considered it good value for money and I now have a wagon which I am proud of. I have no

relationship to any of the traders mentioned in this review but in conclusion I would recommend this kit to anyone

who is fascinated by these wagons and fancies a soldering challenge. It is a good example of a highly detailed well researched

product by a small supplier who deserves much credit for bringing it to market. If Mr Harvey follows it up with other kits, I for one

will be interested.

One of these wagons is not really enough on its own. Perhaps if you all build one each we could run a proper train of them at Telford.

Peter Harvey, the kit’s designer, was sent a copy of this article and responded:

“Well, having read Peter’s story I must thank him. He has written a fine article, and I can tell that he enjoyed the build which

pleases me.”

Air pipes