A simple coach grab handle jig

By Tommy Day

OVER THE YEARS I’ve made a good number of coach grab handles for various types of coaches, most have been simple bending of wire, generally 0,7mm brass or nickel silver, and I’ve always used a pair of small nosed pliers, using the taper on the jaws to get the width of the ‘U’ shaped bend.

Recently I’ve completed a pair of Westdale single unit railcars (class 122), these have seven doors down each side, making a total of 28 grab handles, in addition they are not just ‘straight U’ bends, but are also folded over at 90 degrees.

As I have been reviewing the ‘My Workbench’ Guild Forum threads for useful ideas to put into the Technical hints and tips section on the Guild website, one really useful snippet I’ve not seen before was posted by Mike Sandell on the ‘Kirk Coach Builds’ thread by Rob Pulman, which I thought I would try and has worked out fine, is as follows : -

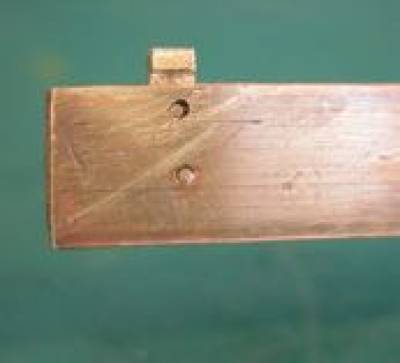

Photo 1

Photo 1 Photo 2

Photos 1 and 2 show the tool, made from a strip of 1/2 in x1/16 in brass, with an offcut of the same brass to the width of the grab handle ‘legs’, soldered (and rivetted badly!) protruding above the main bar, another small piece of x 1/16 in brass is soldered to the offcut creating a gap to the wire thickness. Note that the two parts are rivetted

together so that the offcut can be soldered on without them coming apart.

Photo 2

Photos 1 and 2 show the tool, made from a strip of 1/2 in x1/16 in brass, with an offcut of the same brass to the width of the grab handle ‘legs’, soldered (and rivetted badly!) protruding above the main bar, another small piece of x 1/16 in brass is soldered to the offcut creating a gap to the wire thickness. Note that the two parts are rivetted

together so that the offcut can be soldered on without them coming apart.

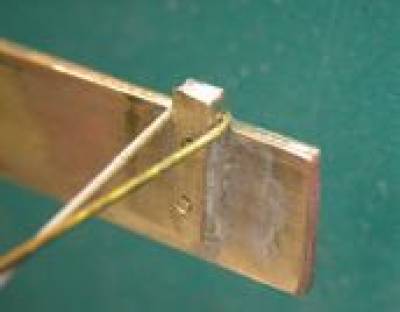

The wire is bent at 90 degrees with the pliers, and then

inserted into the groove as in the photo

The wire is bent at 90 degrees with the pliers, and then

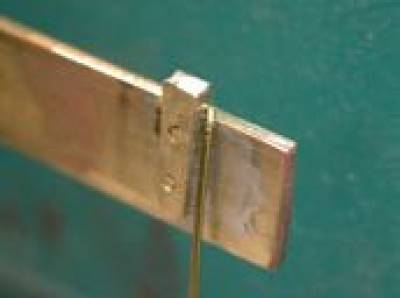

inserted into the groove as in the photo  The wire is then bent round the jig, and squeezed with the pliers to make a sharp angle.

The wire is then bent round the jig, and squeezed with the pliers to make a sharp angle. Both legs are then bent down and squeezed again with the pliers.

Both legs are then bent down and squeezed again with the pliers. The grab handle is then removed from the jig and cut to length, chemically blackened and glued into the railcar body grab handle holes. I had two handles out of the first 28 that didn’t quite fit.)

The grab handle is then removed from the jig and cut to length, chemically blackened and glued into the railcar body grab handle holes. I had two handles out of the first 28 that didn’t quite fit.)